MIL-V-27296C

* 4.3.2 Atmospheric conditions. Unless otherwise specified, all tests required by this specification shall be

0

0

made at an atmospheric pressure of 28 to 32 inches of mercury, at a temperature of 77 F to + 18 F, and a relative

humidity of 60 t0 80 percent. Where tests are made with an atmospheric pressure or temperature substantially

different from the above values, proper allowance shall be made for the change in instrument reading.

4.3.3 Gas. The high pressure gas used in testing the valves shall be oxygen conforming to type I of MIL-O-

27210; water-pumped nitrogen conforming to type I, class I, grade B of BB-N-411; or compressed air conforming

to Federal Specification BB-A-1034, COmpressed air breathing, source II, Grade B.The water content shall be 0.3

mg per liter maximum. If nitrogen or air is used, appropriate density correction factors shall be applied to the

rotometer used, not only to correct the effect on the meter, but also on the performance of the valve with lower

density gas.

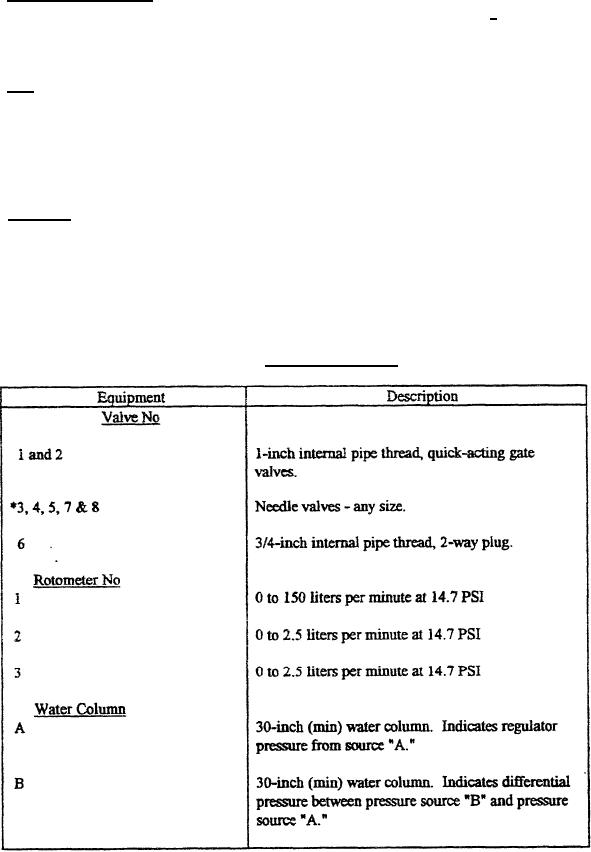

4.3.4 Test stand. The tests specified (see 4.6.2,4.6.3,4.6.6,4.6.7, 4.6.8,4.6.9, and 4.6.15) shall be conducted

by means of a test stand conforming to figure 6. The other tests shall be conducted by means of any suitable

apparatus. The equipment for the test stand shall conform to table I. As an alternate, test equipment capable of

performing the identicle test specified herein may be used when specifically approved by the procuring activity.

All tests of valves shall be accomplished on the test stand with a gasket that duplicates the exhalation port and

anti-king chamber of the MBU-5/P oxygen mask conforming to MIL-M-27274 or the hardshell exhalation

chamber of an MBU-12/P mask conforming to MIL-M-87163, as applicable.

TABLE I Test stand equipment

7

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business