MIL-DTL-87223A (USAF)

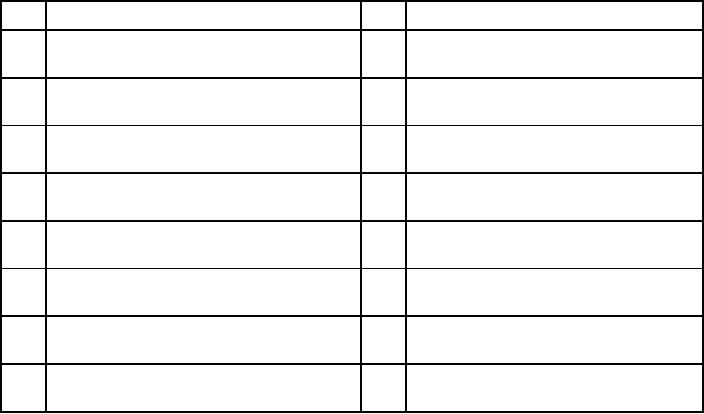

TABLE III. Classification of defects for visual examination of the valve.

Critical

Minor

1

Material imperfections foreign matter

201

Marking missing, insufficient,

embedded.

incorrect, permanent.

2

Surface unclean, rough, misaligned, or

containing cracks, nicks, or other flaws.

3

Any component missing, malformed,

fractured, or otherwise damaged.

4

Any component loose or otherwise not

securely retained.

5

Incorrect assembling or improper

positioning of components.

6

Any functioning part that works with

difficulty.

7

Faulty workmanship or other

irregularities.

8

Linkage interference or component

binding.

4.5.2 Minimum operating acceleration force.

The valve shall be subjected to inlet pressures of 30, 100, 200, and 300 psig. The acceleration

force required to open the valve at each inlet pressure shall be as specified in 3.5.1.

4.5.3 Outlet pressure regulation.

A tank shall be connected as specified in 4.4.4.1 during this test. A source of pressurized gas

shall be connected to the valve inlet port. The inlet gas pressure shall be increased and

maintained at 30 psig while acceleration forces of 2, 4, 6, 8, 10, 8, 6, 4, 2, and 1Gz are applied,

in this order, to the valve. Each force shall be maintained for at least 10 seconds before the

next force is applied. The inlet pressure shall be increased to 100, 200, and 300 psig, and the

test repeated at each of these inlet pressures. The outlet pressure shall be as specified in 3.5.2.

4.5.4 Leakage.

With a force of 1 Gz applied to the valve, the inlet flow to the valve at an inlet pressure of 30,

100, 200, and 300 psig shall not exceed that specified in 3.5.3.

4.5.5 Anti-chatter.

A tank shall be connected as specified in 4.4.4.1 during this test. A source of pressurized gas

shall be connected to the valve inlet connection. The inlet pressure shall be increased and

maintained at 30, 100, 200, and 300 psig. At each pressure level the valve shall be fully opened

manually, by pressing the push-to-test button, and held open a sufficient length of time to

determine that there is no evidence of chatter when there is air flow through the relief valve.

14

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business