MIL-PRF-26392E

in 4.3.1 and the sampling tests in 4.3.2.

4.3.1 Individual tests. Each dummy converter shall be subjected to the following

examination and tests:

a. Examination of product (see 4.6.1).

b. Capacitance at room temperature (see 4.6.2).

4.3.2 Sampling tests. One percent of each order (a minimum of one dummy converter),

shall be subjected to the following tests:

a. Capacitance at low temperature (see 4.6.3).

b. Capacitance at high temperature (see 4.6.4).

c. Case leakage (see 4.6.5).

4.4 Inspection conditions. Unless otherwise specified, all tests shall be performed at

ambient temperature and pressure, and not greater than a relative humidity of 80 percent.

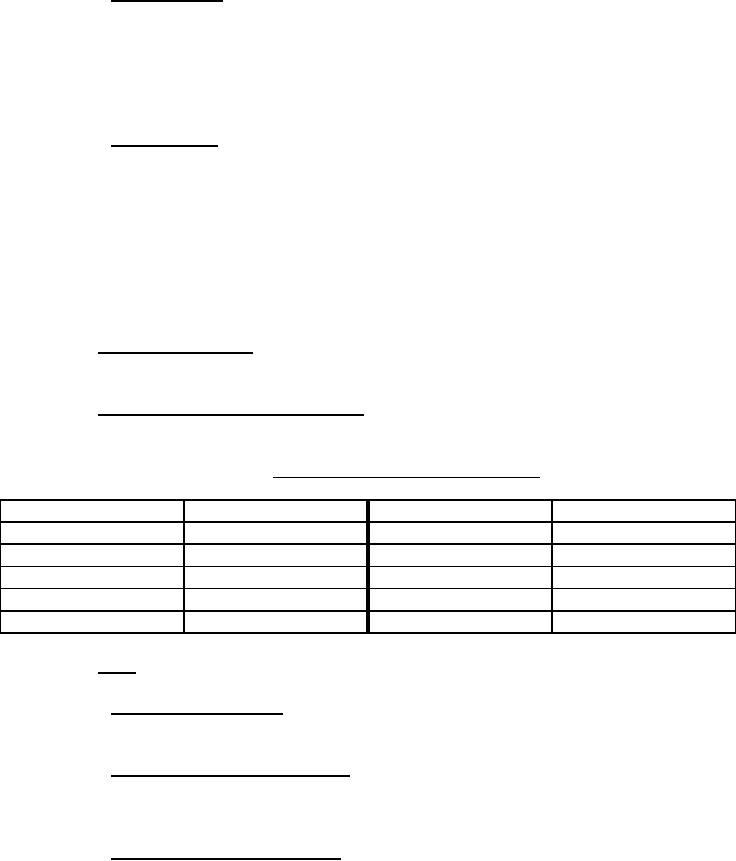

4.5 Requirements cross-reference matrix. Table I provides a cross-reference

matrix of the section 3 requirements tested or verified in the paragraphs below.

TABLE I: Requirements cross-reference matrix

Requirement

Verification

Requirement

Verification

3.1

4.2

3.5.2

4.6.5

3.3

4.6.1

3.5.3

4.6.6

3.4.1

4.6.1

3.5.4

4.6.7

3.4.2

4.6.1

3.5.5

4.6.1

3.5.1

4.6.2, 4.6.3, 4.6.4

3.5.6

4.6.1

4.6 Tests.

4.6.1 Examination of product. Each dummy converter shall be examined to

determine conformance to materials, weight, and dimensions.

4.6.2 Capacitance at room temperature. Using a capacitance measuring instrument, the

capacitance at room temperature shall be 123.5 ± 1.0 pF for Type I dummy converters and

303.5 ± 2.5 pF for Type II dummy converters.

4.6.3 Capacitance of low temperature. The dummy converter shall be cold soaked at a

temperature not greater than -65°F for no less than 8 hours. While still at this temperature, the

capacitance shall be 123.5 ± 1.0 pF for Type I dummy converters and 303.5 ± 2.5 pF for Type

4

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business