MIL-DTL-19246E

4.6 Gas conditions. The gas used in testing the connector assemblies shall be oxygen

conforming to MIL-PRF-27210, type I.

4.6.1 Temperature and pressure conditions. Unless otherwise specified, inspections shall be

conducted at local ambient temperatures and barometric pressure. Corrections shall be made to

provide agreement with the temperature and pressure calibration of the instruments. Inspection

data provided by any instrument not calibrated to normal temperature and pressure (NTP)

conditions shall be corrected to determine NTP requirements. NTP conditions shall be 29.92

inches of mercury and 70 °F.

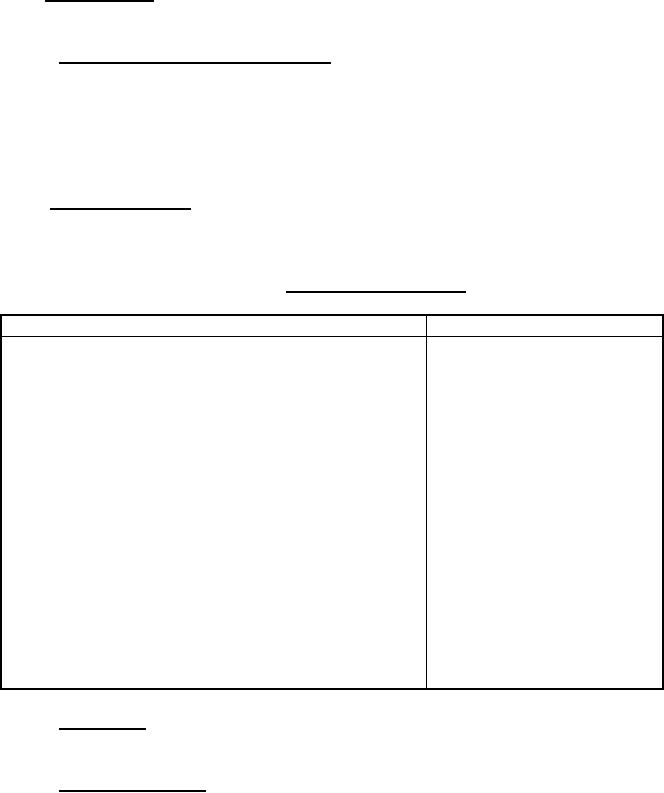

4.7. Visual examination. Every connector shall be examined visually for critical defects to

determine conformance to this specification and to MS22016. Table II shall be used to classify

the defects found.

TABLE II. Classification of defects.

CRITICAL

MINOR

1.

Material imperfections - foreign matter embedded.

201. Marking - missing,

insufficient, incorrect,

2.

Surface - unclean, rough, misaligned, or

illegible, or not permanent.

containing cracks, nicks, or other flaws.

3.

Any component missing, malformed, fractured,

or otherwise damaged.

4.

Any component loose or otherwise not

securely retained.

5.

Incorrect assembling or improper positioning

of components.

6.

Any functioning part that works with difficulty.

7.

Faulty workmanship or other irregularities.

4.7.1 Dimensions. The connector shall be checked dimensionally to determine

conformance to MS22016.

4.7.2 Disconnection force. The connector shall be installed in a connector assembly

conforming to MS22058. The connector assembly shall then be subjected to a straight pull

parallel to the longitudinal axis. An average of five pulls conducted at five second intervals shall

8

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business