MIL-DTL-9370E

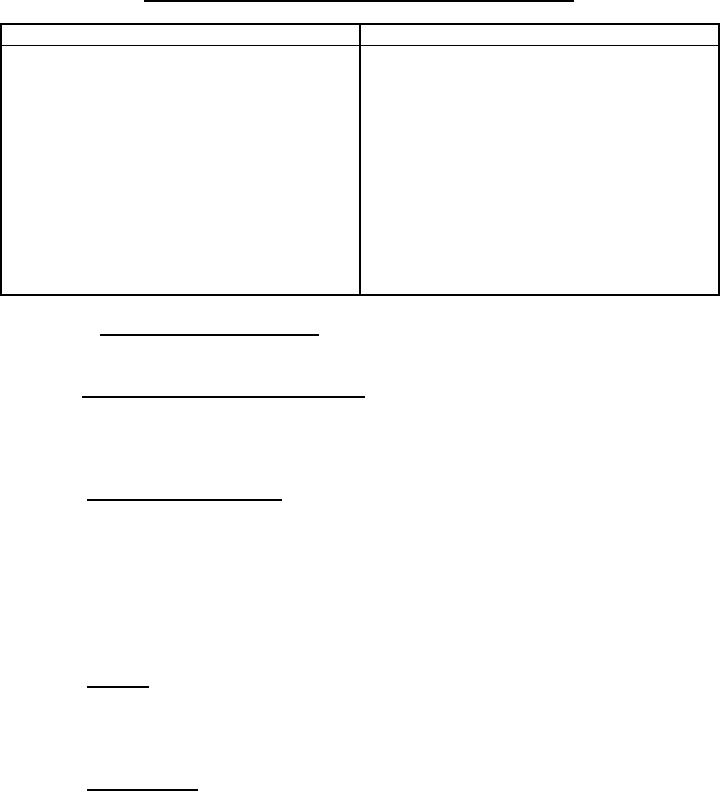

TABLE III. Classification of defects for visual examination of the valve. (Continued)

Critical

Minor

4.

Any component loose or otherwise not

securely retained.

5.

Incorrect assembling or improper

positioning of components.

6.

Any functioning part that works with

difficulty.

7.

Faulty workmanship or other

irregularities.

4.6.1.2 Dimensions and configuration. The dimensions and configuration shall be checked

to determine conformance to the specified dash number of MS24350.

4.6.2 Minimum operating acceleration force. A buzzer shall be installed as specified in

4.5.4.1 during this test. The pressure regulating valve shall be subjected to inlet pressures of 30,

100, 200, and 300 psi. The acceleration force required to open the valve at each inlet pressure

shall be as specified in 3.5.1.

4.6.3 Outlet pressure regulations. A buzzer shall be installed as specified in 4.5.4.1 and a

tank connected as specified in 4.5.4.2 during this test. A source of pressurized gas shall be

connected to the inlet port and a mercury manometer connected to the outlet. The inlet gas

pressure shall be increased and maintained at 30 psig while acceleration forces of 2g, 4g, 6g, 8g,

10g, 8g, 6g, 4g, 2g, and 1g are applied in this sequence to the valve. Each force shall be

maintained for at least 30 seconds before applying the next force. After completing the 30 psig

inlet pressure phase, the inlet pressure shall be increased to 100, 200 and 300 psig, and the test

repeated at each of these inlet pressures. The outlet pressures shall be as specified in 3.5.2.

4.6.4 Leakage. A source of pressurized gas shall be connected to the inlet connections, and

a flow meter shall be connected to the outlet connection. The inlet pressure shall be increased to

and maintained at 300 psig for at least one minute while a force of 1g is applied to the valve.

The leakage shall be not greater than that specified in 3.5.3.

4.6.5 Anti-chattering. A buzzer shall be installed as specified in 4.5.4.1 and a tank

connected as specified in 4.5.4.2 during this test. A source of pressurized gas shall be connected

to the inlet connection. The inlet pressure shall be increased to and maintained at 300 psig. The

pressure regulating valve shall be fully opened manually and held open until there is a flow

10

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business