MIL-DTL-9370E

4.5.2 Acceleration force. When conducting the tests specified herein, the acceleration force

shall be applied to the valve in the direction specified on MS24350. Weights may be used to

simulate the acceleration force; however, the qualifying activity reserves the option to calibrate

the valve on a centrifuge. In either case, the total g force shall be 1g plus added test weight.

4.5.3 Test medium. The test medium used in conducting the tests shall be air or nitrogen.

The moisture content of the air shall be not greater than 0.02 milligram per liter. The nitrogen

shall conform to A-A-59503, type I, class 1, grade 3.

4.5.4 Test equipment.

4.5.4.1 Buzzer. When specified, a buzzer conforming to Line Electric Co. AC buzzer, style

MC, 115 volt, 60 cycles, or its equivalent shall be used. The buzzer shall be installed on the

mounting plate of the valve in such a manner so as to produce vibration. The buzzer shall be

employed to prevent or overcome frictional lag inherent in the valve and to simulate aircraft

flight conditions.

4.5.4.2 Tank. When specified, a tank having a volume of approximately 10 liters shall be

used. The tank shall be connected to the outlet port of the pressure regulating valve.

4.6 Inspection methods.

4.6.1 Visual examination.

4.6.1.1 Valve. The valve shall be examined visually for defects to determine conformance

with this specification. The classification of defects, table III, shall be used to classify the

defects found.

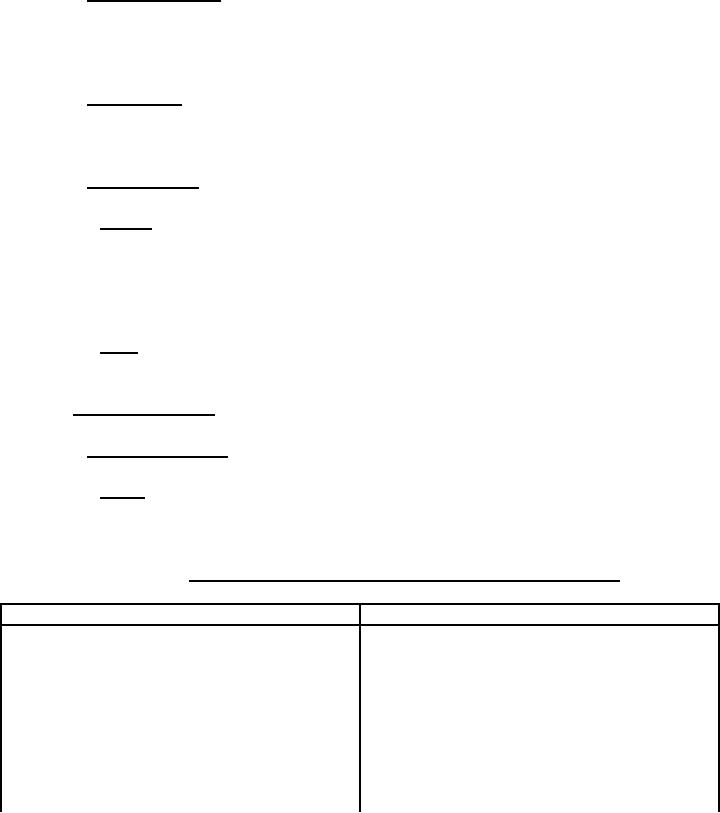

TABLE III. Classification of defects for visual examination of the valve.

Critical

Minor

1.

Material imperfections - foreign matter

201. Marking - missing, insufficient,

embedded.

incorrect, illegible, or not permanent.

2.

Surface - unclean, rough, misaligned, or

containing cracks, nicks, or other flaws.

3.

Any component missing, malformed,

fractured, or otherwise damaged.

9

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business