MIL-DTL-5886H

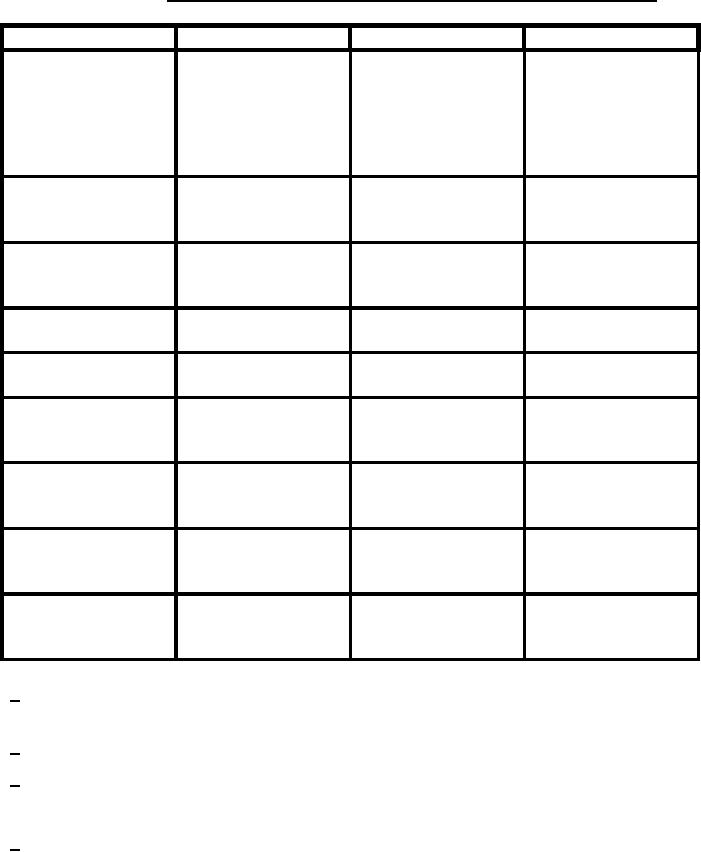

TABLE I. Sample size, acceptance criteria, tests and examination of cylinders.

Inspection

Method paragraph

Sample size

Acceptance criteria

Visual examination

4.5.1

Every cylinder for

Reject all units with

(see classification of

critical defects. 1/

any. critical defects.

defects)

Inspection level S-2

Acceptance number

for minor defects

zero, rejection

number 1 for minor

defects.

Dimensions

4.5.1.1

1/ Inspection level

Acceptance number

S-2

zero, rejection

number 1.

Cleanliness

4.5.2

1/ Inspection level

Acceptance number

S-2

zero, rejection

number 1

Leakage

4.5.3

Every cylinder

Reject all defective

units.

Permanent

4.5.4

Every cylinder

Reject all defective

volumetric expansion

units.

Burst pressure 2/

4.5.5

1/ Inspection level

Acceptance number

S-2

zero, rejection

number 1.

Macrostructure

4.5.6

1/ Inspection level

Acceptance number

S-2 3/

zero, rejection

number 1.

Radiographic

4.5.7

1/ Inspection level

Acceptance number

inspection

S-2

zero, rejection

number 1.

Physical properties

4.5.10

1/ Inspection level

Acceptance number

S-2 4/

zero, rejection

number 1.

1/ The sample size shall be based only on the applicable sample size code letter corresponding to

the specified inspection level of ASQ-Z1.4.

2/ This is a destructive test (see 6.2).

3/ The burst pressure sample may be used. However, the longitudinal section shall be taken at

locations not affected by the burst point.

4/ One sample from unaffected area of burst pressure sample unit.

15

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business