MIL-DTL-87255A(USAF)

4.5

Inspection methods

4.5.1

Visual examination

4.5.1.1 Valve.

Each valve selected as a sample unit from the lot shall be thoroughly examined visually and

checked dimensionally for defects to determine conformance to this specification with respect to

materials, design, construction, marking, and workmanship. Defects shall be classified in

accordance with table V.

4.5.1.1.1 Dimensions and configuration.

The valves shall be examined for defects in dimensions and configuration. Any dimensions or

configuration not conforming to the requirements of the applicable assembly number of figures

1, 2 or 3, as applicable, shall be classified as a major defect.

4.5.2 Minimum operating acceleration force.

At the start of this test the press-to-test button shall be depressed to ensure air flow at the

outlet. No air flow at the outlet with the button fully depressed shall be cause for failure of this

test. The valve shall be subjected to inlet pressures of 30, 70, 150, and 300 psig. The

acceleration force required to open the valve at each inlet pressure shall be as specified in

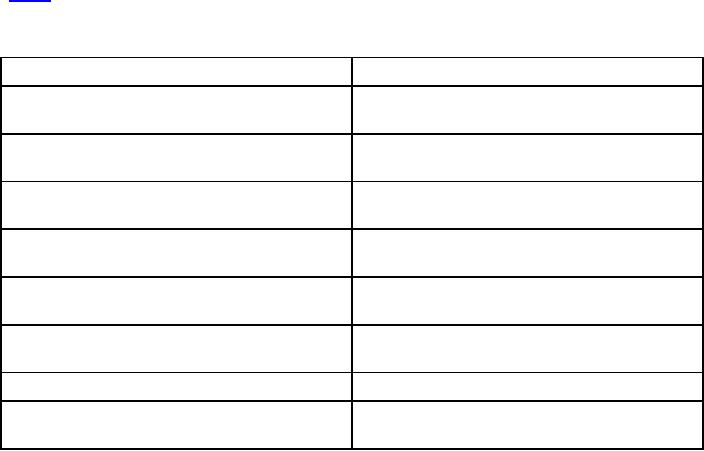

T AB L E V. Classification of defects for visual examination of the valve.

Critical

Minor

1. Material imperfections foreign matter

201. Marking missing, insufficient,

embedded.

incorrect, permanent

2. Surface unclean, rough, misaligned, or

containing crack, nicks, or other flaws.

3. Any component missing, malformed,

fractured, or otherwise damaged.

4. Any component loose or otherwise not

securely retained.

5. Incorrect assembling or improper

positioning of components.

6. Any functioning pan that works with

difficulty.

7. Faulty workmanship or other irregularities.

8. Linkage interference or component

binding.

17

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business